In partnership with the University of North Carolina at Charlotte, researchers and faculty from Lehigh University’s Energy Research Center (ERC) and the Advanced Technology for Large Structural Systems (ATLSS) Engineering Research Center were recently awarded funding from the Department of Energy’s National Energy Technology Laboratory. These Centers are part of Lehigh’s Institute for Cyber Physical Infrastructure and Energy. The project, Improvement of Coal Power Plant Dry Cooling Technology through Application of Cold Thermal Energy Storage, will receive $1.5M in funding under the Crosscutting Research for Coal-Fueled Power Plants program. The Lehigh team includes:

John Fox, Assistant Professor of Civil & Environmental Engineering

Clay Naito, Professor of Civil & Environmental Engineering

Sudhakar Neti, Emeritus Professor of Mechanical Engineering and Mechanics and Senior Scientist at the Energy Research Center

Carlos Romero, Director and Principal Research Scientist at the Energy Research Center

Muhannad Suleiman, Associate Professor of Civil & Environmental Engineering

Zheng Yao, Research Scientist at the Energy Research Center

Together, the UNCC-Lehigh team represents more than 50 years of experience in power generation technologies and the power generation industry. The team will be led by Principal Investigators Dr. Nenad Sarunac (UNCC) and Dr. Carlos Romero (Lehigh) and includes industry collaborator Worley, a leading global provider of professional project and asset services in the energy, chemicals and resources sectors. Additional industry advisors include the Baltimore Aircoil Company and Gas Technology Institute.

The project entails developing, designing, and evaluating a robust and cost-effective system for improving performance of mechanical draft dry cooling tower and air-cooled condensers, which are used to cool the steam exiting power plant turbines with air instead of water. Though dry cooling systems reduce water consumption at coal power plants, they are generally more costly and less efficient. In developing innovative, scalable, and cost-effective technology to improve dry cooling in power plants, the team will help overcome these challenges to increase efficiency without using any additional water. Dr. Romero explains, “Water withdrawal by thermoelectric power plants in the US is of the order of 50 trillion gallons, representing a large share of US freshwater withdraw--there is a great interest in reducing the water footprint of these plants.” The team expects that the resulting technology will have industrial, commercial, and residential power generation applications beyond coal-fired power plants (e.g., natural gas combined cycles and concentrated solar power systems).

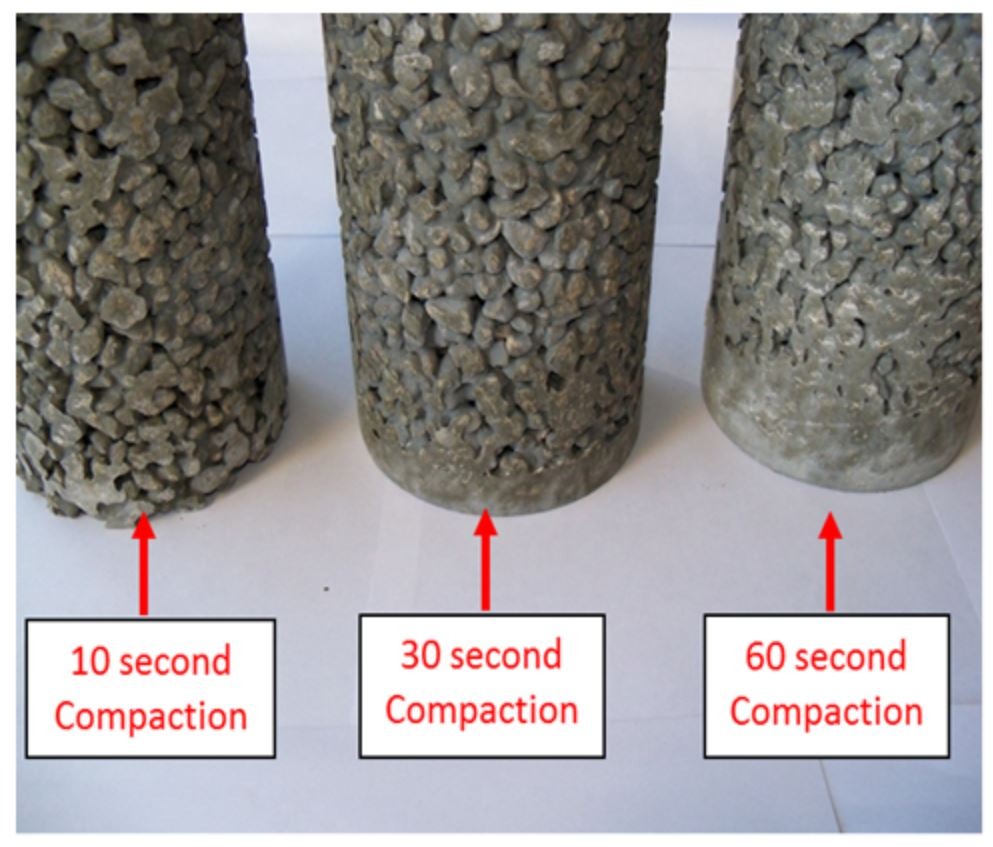

To achieve these goals, the team will develop an integrated direct heat exchanger and thermal energy storage unit that allows the system to operate at a minimum cooling temperature by taking advantage of daily temperature fluctuations (i.e., store “cold” energy during night-time when the ambient temperature is low and use it to pre-cool air entering the air-cooled condensers during the hottest period of the day). This approach draws upon the team’s previous work, funded by DOE ARPA-E, of including Phase Change Material (PCM) engineering in the temperature range of interest and system integration/testing at the laboratory and prototype scale and National Science Foundation funding on developing pervious concrete and its applications for different civil infrastructure applications.