Imagine you have 100 Popsicle sticks, a jar of glue, and a few teammates, and you need to build a bridge.

You’ll have to make a lot of choices: what type of truss bridge configuration should you build to resist an increasing load? How can you allocate your time among the fundamental tasks of design, construction, and testing? Where and how do you use more sticks–or more glue–to create strength? How do you divide the tasks among your team? How do you test your bridge? How do you determine what its point of failure is?

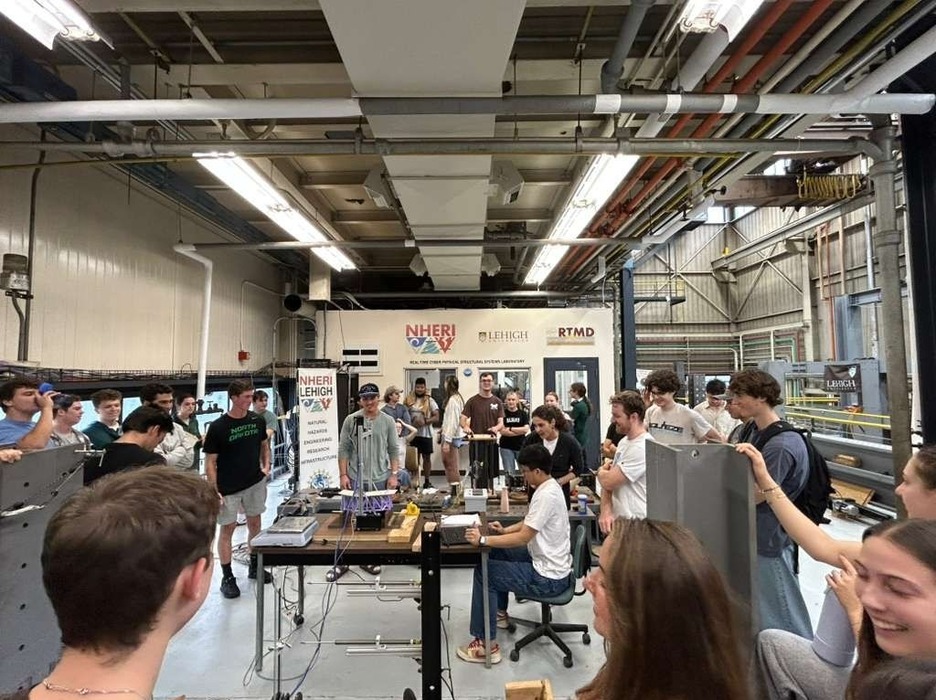

This was the scenario faced by the 45 students in Assistant Professor of Civil and Environmental Engineering and Environment Professor Claudia Reis’s CEE159 class at Lehigh University early in the fall 2025 semester. Eight teams spent three weeks planning, research, designing, and constructing some form of truss bridge. At the end, teams submitted their final build to testing at the ATLSS (Advanced Technology for Large Structural Systems) Engineering Research Center, where an actuator was used to test the bridge’s capacity to carry an increasing displacement. The bridge was instrumented to monitor and record the concentrated load.

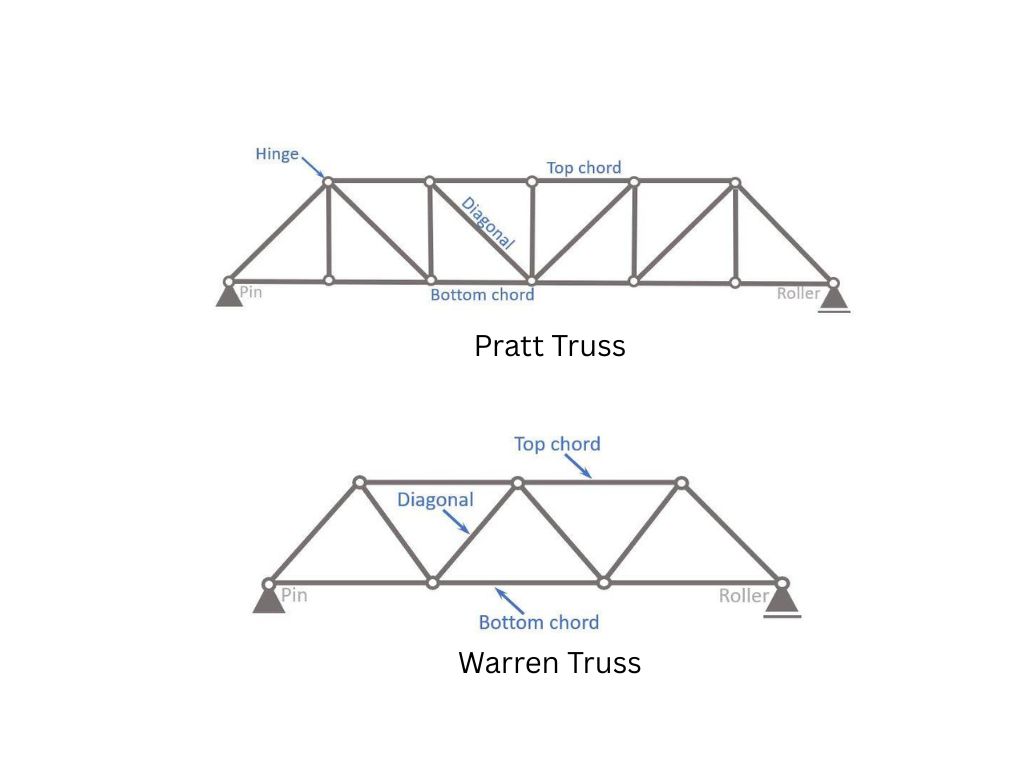

A short primer for non-bridge engineers: a truss bridge design is based on a composition of triangles. Multiple triangles, configured and arranged in different ways for different bridge types, support and distribute loads, sometimes assisted by crossbars positioned in transverse directions. It’s an efficient design that has many configurations, and represents a design that CEE159 students are studying this semester. Professor Reis preferred that the students work with one of three basic truss designs: Pratt, Warren, and A-frame. For the competition, the students also needed to take into account the material management to build their specimen: wood and glue, neither one known for high strength.

Engineers face constraints, and the CEE159 students were no exception. The bridge model had to fulfill minimum dimensions criteria (40cm x10cm, approximately), and wood-and-glue materials have clear limitations, so building with them allowed students to see the basic tradeoffs that engineers face: time, cost, and quality. They had limited materials, limited time to design and build, and they had to plan their work carefully, factoring in glue-drying time as they built each component in sequence. While all teams had the same quality of materials, they could use various design principles to increase the quality of their builds. Dr. Reis provided an opportunity: the teams could buy 10 more sticks at the price of a 1-point deduction from their point total from the project. “In the end,” Reis said, “the challenge is to have an efficient configuration for the structure. You need to use as little material as you can, with the most resistance you can build.”

Students constructed their bridges at the ATLSS Engineering Research Center on Lehigh’s Mountaintop Campus. Using information from their textbook and calculations, the groups designed for strength. While some students drew on intuition, others were “more analytical and were doing a lot of calculations and using computational resources,” Reis says.

The groups considered their truss design options and chose the structure based on how strong they could make the bridge while using the lightest amount of material: most chose a variation on Pratt or Warren, while one went with an inverted A-frame. As one team said of their Warren truss, “It’s lighter with fewer connections” because the efficiency of the bridge was determined using a simple strength-to-weight ratio. Other design considerations included angle measurements, deck construction, and reinforcement placement. Reis was impressed by how seriously the students took construction: she says students took construction seriously, working all afternoon, attending club meetings or sports practice, then returning to ATLSS to consider refinements.

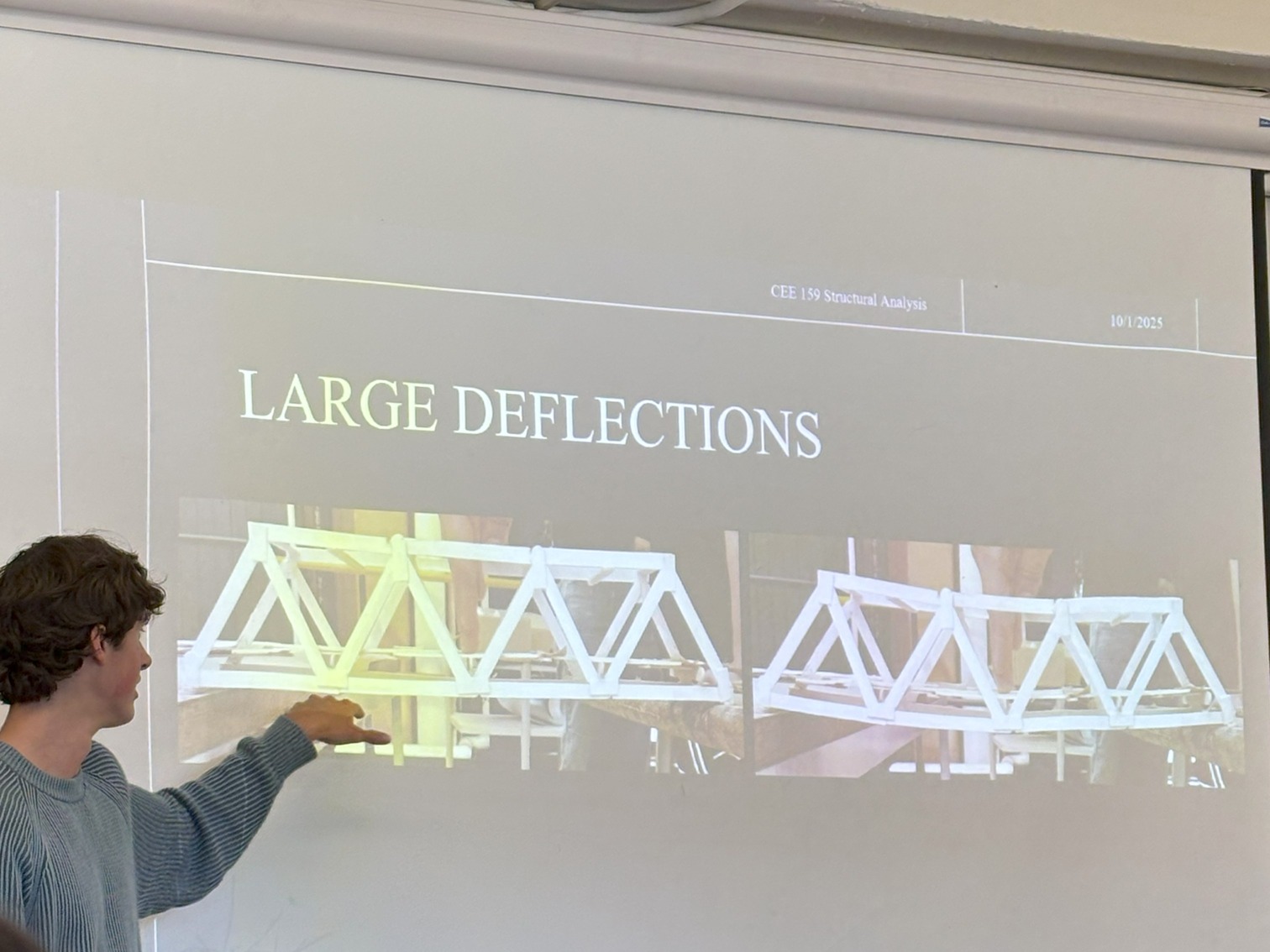

Testing took place at ATLSS using the same actuators that researchers use for their externally funded sponsored research projects. Reis says she took them to ATLSS precisely for this reason: “we have valuable research resources, all the instrumentation and everything ready—we use an actuator to impose a controlled displacement and load cells to do the correlation with the resisting force of the bridge model.” Each group determined the placement of their build on the actuator with the condition of testing the model at the middle span. Each test ended when the building group decided their bridge had had enough based on a real-time monitoring of the bridge response to the imposed displacement. Sometimes the students identified the plateauing resistance of the model and stopped the test to keep their models as souvenirs (and decoration items for some of the students’ bedrooms); others kept the test running out of curiosity to see how the model would progressively deform and identify the first pieces to break. After the monitored test, some students even tested the performance of their truss designs by standing on their 40cm-long model, which weighed about 0.3 lb. on average.

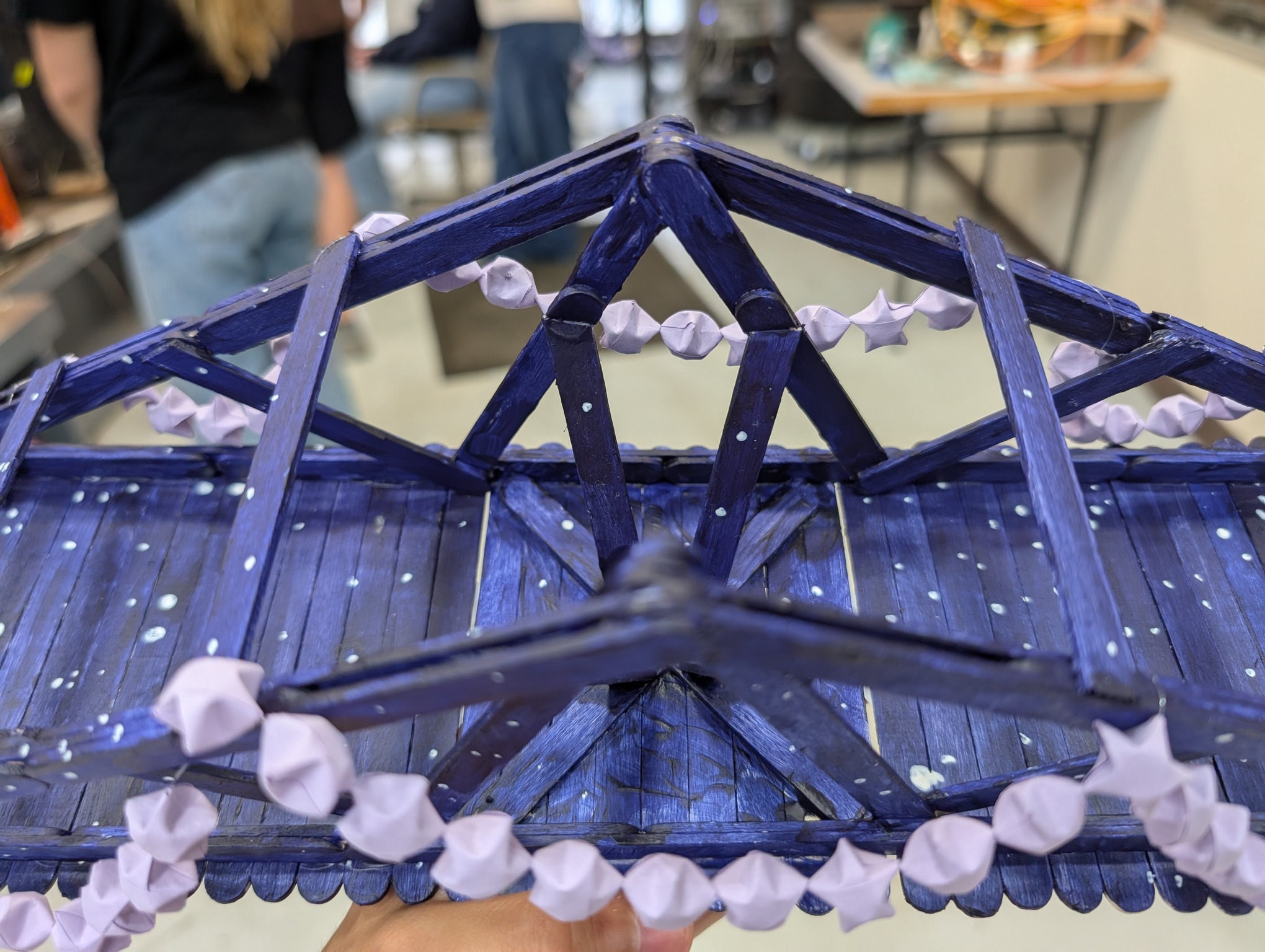

After the tests, groups presented to the class, discussing their design process, aesthetic considerations, concerns about strength, and their approaches to the construction of the deck, from parallel sticks to staggered placement to girders and braces. They also discussed issues such as their glue application strategies: a lighter application, as with a paintbrush, would keep the overall weight low, but a heavier hand would increase strength. Some groups applied glue more heavily in areas that would feel more stress. Others, like the Bridge Heads, created dovetail-like joints to reduce material weight, brushed on glue with a paintbrush, and cut gussets to reinforce high-stress joints. It worked: They did have the lightest bridge–but it also carried the lightest load. As they said, “Our bridge had the lightest weight, which was our goal–and held the lowest load, not our goal.”

Most importantly, the groups reflected on what they learned from the exercise, reflecting on the choices they made and how each might have contributed to their bridge’s success or failure. Many considered the glue the weak link and wished for wood glue; others reflected ruefully on their planning process, while others wanted to reconfigure their bracing, chords, or angles.

This is a common early engineering exercise, Reis says, introducing students to a static load, which is a relatively constant force or displacement; for more advanced learning, they’d deal with dynamic loads such as wind, earthquakes, and other less predictable forces. She says, “for me, it's a very complete exercise for future engineers, because they need to consider a lot of factors when they are actually doing structural analysis and design.” Dr. Reis also had the goal of introducing the students to a laboratorial environment and promoting engagement and awareness of the students to Lehigh’s high-quality research.

For now, though, the students in CEE159 have gotten a taste of engineering and its economics, and even the weakest bridge has delivered strong lessons. Which is a good thing, because someday we’ll all be driving over one of their bridges.

Winning groups: Lunar Crossing (below, top) for Creativity and Team Heart (below, bottom) for Performance

Professor Reis thanks her TA, Engr. Jiaxing Zhou, a PhD student in Civil and Environmental Engineering, as well as ATLSS Systems Manager, Tommy Marullo, and ATLSS Director, Professor James M. Ricles, for their help and use of the facility.

Photos courtesy Claudia Reis.