Lehigh University’s Arup K. SenGupta, Professor of Civil and Environmental Engineering, and Carlos Romero, Director of the Energy Research Center and Research Professor of Mechanical Engineering and Mechanics, along with researchers at Advanced Cooling Technologies (ACT) of Lancaster, Pennsylvania, led by Dr. Joshua Charles, have been awarded a DOE STTR grant for Phase II of their research, “Direct Air Capture by Ion-Exchange Sorbent and Low-Grade Heat.” This new award extends the research of Phase I, which started in 2022 and focused on creating a lab-scale direct air capture (DAC) technology. The highly competitive STTR award is intended to enable small businesses explore the technological potential of basic science.

Anthropogenic CO2 (carbon dioxide) emissions are widely accepted as the primary driver of global climate change. While renewable energy technologies are helping transform energy systems for a net-zero carbon future, meeting climate goals will also require large-scale atmospheric CO2 capture systems that remove carbon directly from the air. Direct air capture is one type of carbon removal technology that shows promise today and will likely be part of a larger carbon removal portfolio.

The researchers at Lehigh and ACT are focusing on a DAC technology that mitigates the harms of greenhouse gases (GHG) by acting as a sort of filtration system, removing CO2 directly from the air. ACT and Lehigh University's new ion-exchange DAC system captures CO2 in a fundamentally new way. The basic scientific tenet of the proposed acid-base ion-exchange DAC system relies on the unique weak acid–weak base (WAWB) properties of CO2. When dissolved in water, CO2 produces a weak acid (H2CO3), while its conjugate anion (HCO3-) is essentially a weak base (better known as alkalinity). By appropriately tailoring an ion-exchange resin, the project team has developed a simple-to-operate two-bed system that can selectively capture CO2 from the air and can subsequently strip, or desorb, it to produce pure gaseous CO2.

In Phase I, the team used widely available commercial adsorbent resins (porous types that act like a sieve) and demonstrated CO2 capture rates of 90% with thermal regeneration of the adsorbent occurring at temperatures as low as ~50 degrees C (about 122 degrees F). The system can utilize either a low-grade heat source medium (such as industrial waste or geothermal) or an electrically derived weak base solution to regenerate the capture sorbent.

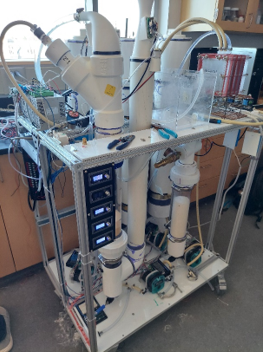

The key aspects of the technology that make it attractive for further development and use on a wide scale are that its basic parts, such as the adsorbent resins, are commercially available at relatively low cost, and that the system is modular, minimizing manufacturing and deployment costs. In Phase II, the system will be refined, with individual components being improved and tested as they ramp up for larger-scale tests. The researchers are aiming to decrease overall energy consumption by upward of 29 percent and to reduce capture costs to less than $100/ton. A system prototype will be built at ACT and deployed for testing under an operational environment at the Energy Research Center at Lehigh.