Rudy Shankar, Director of Energy Systems Engineering and Institute for Cyber Physical Infrastructure & Energy (I-CPIE) faculty member, is in Phoenix, Arizona this week for Utility Analytics Week 2019. The following are his thoughts from Day 1 of the conference.

Overview

This day consisted of a number of utilities presenting 10-minute “Innovation Shares” sessions in the morning and afternoon, interspersed with a general session. This blog addresses significant ideas presented--from "low-hanging fruit" ideas, like uilitizing analytics to save costs, to more sophisticated “number crunching” in the cloud that would digest large amounts of data to produce near real-time results.

APS Generation Strategy (Jacob Tetlow)

The opening address was made by Jacob Tetlow, the Vice President of T&D for APS, the host utility for a large part of Arizona. APS has nearly 3 million customers whose mix of 10 GW is almost 50% clean (i.e., non-fossil based) with connection to the California Independent Service Operator (CAISO). Its solar penetration is 4 years ahead of schedule, with an expected 40k MW of solar in next decade. Excess renewable capacity in California sometimes creates a negative price power (up to $100K per day) for APS to take power from them. However, large-scale deployment of energy storage may change the dynamics. In response, APS has a goal of installing up to 1 GWh of energy storage in the coming years.

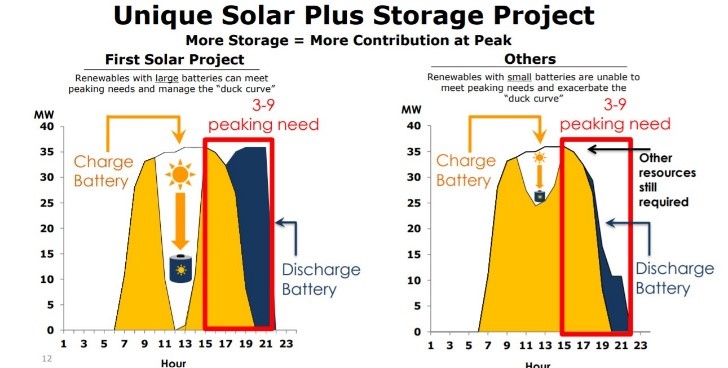

However, energy storage is not a one-for-one substitute: 1 MW of solar resource does not equate to 1 MW of storage available. It is most likely 2 to 3 times less and one must plan for storage being able to replace from 33% to 50% of available solar resource. The time when this is deployed is also key, as shown in the figure.

There are other variants from conventional thinking: while South facing PVs may offer the maximum insolation, West facing solar may be most useful to augment evening peaks which require a large number of generation assets to ramp from sunset to the evening peak. The speaker mentioned that the future focus of analytics will likely be:

AMI meters and getting the full value to the data.

Moving from time based to condition based maintenance.

Looking at larger scale battery deployments for frequency response and “wires” responses.

Tennessee Valley Authority - Grid Management with Analytics (Neelanjan Patri)

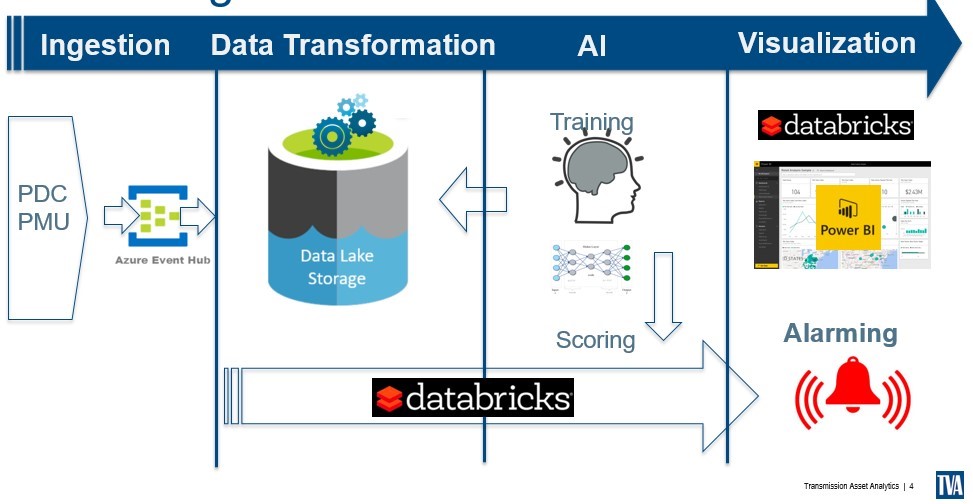

The largest contributor to load not served (LNS) comes from transmission equipment issues. Better monitoring and management of transmission assets will improve reliability and reduce costs. For the TVA, the generation lost due to transmission issues over the past three years average 12,200 MWh, with transmission average annual O&M spend $177M. It was believed that high resolution data can help, such as from Phasor Monitoring Units (PMUs), and can assist in preventing outages. Transmission operators estimated 60% reduction in LNS from accurate fault detection, and a 2% reduction to Operations and Maintenance spending would see $3.5M in savings each year. High-resolution data allows visibility into system and equipment conditions, including rapid identification of details such as oscillations and voltage instability.

Realizing that processing such a large volume of data would need special access, TVA worked with Databricks that specialized in managing cloud computing. The data were sampled at over 1000 points per second (1 Khz frequency), several orders of magnitude than the highest resolution typically executed for AMI data (15-minute samples), for example.

The process for data analytics involved pooling the data in a “lake” and developing neural network algorithms that were able to map the data to show anomalies of several attributes chosen. If there were deviations from the norm of any of these attributes, they triggered an alarm for generators on the grid that were candidates for failing. This was a unique method to detect generator anomalies from examining grid data, albeit very highly sampled information.

PPL Electric Utilities - Analytics for Optimized Transmission & Substation Assets (Joel Eline)

Big data and data science are transforming the way PPL Electric does business. From operations, maintenance and customer interactions, to smart delivery and forecasting, data are being used across the business to cut costs and improve performance.

What is now called the “Data Center of Excellence,” started in 2015 with the maintenance engineering team and an issue with poor performing circuit breakers. Traditionally, the oldest circuit breakers were maintained first. But, this maintenance approach seemed to only make performance worse. So, a data scientist joined the team and partnered with the engineers to develop a data-driven maintenance approach. The result? A 35% reduction in maintenance costs and 50% fewer circuit breaker malfunctions.

Seeing the immediate benefits, PPL Electric expanded its number of analysts and formalized the team, which now includes seven members. The pipeline of projects remains full and continues to grow in scope. Because of the team’s work in Q1 2019 alone, the company already reduced spend, saving an estimated $850,000 annually, all while improving performance.

The team, still relatively new, has just started to scratch the surface of big data opportunities. The team is exploring new innovations, like using behavioral analytics to improve customer communications, artificial intelligence for system planning and machine learning for better asset investments at a low cost. The industry is changing, but one thing remains certain: data science will continue to be a key part of how PPL Electric maintains its competitive edge.

Santee Cooper - Continuous Improvement to Optimize O&M Expenses (Julie Jordan)

Santee Cooper is a SC-stated owned utility that owns generating, transmission and distribution assets. They embarked on a program to save costs by “breaking silos” and identifying cost savings, both in real costs to avoided costs. Their target was to achieve $3M but this year so far they have exceeded that amount. Much of their savings was from O&M strategies adopted for their coal-ash pond storage.