Carlos Romero, Director of the Energy Research Center (ERC), co-Associate Director of I-CPIE, and a faculty member of the Mechanical Engineering and Mechanics department, and Zheng Yao, Principal Research Scientist at the ERC, have been awarded a DOE STTR (Department of Energy Small Business Technology Transfer) award for Phase II of their proposal, “Machine Learning Enhanced LIBS to Measure and Process Biofuels and Waste Coal for Gasifier Improved Operation.” The proposal team includes Energy Research Co. (ERCo) in Plainfield, New Jersey (small business lead), GTI Energy and SpG Consultants. Beginning in August 2023, the two-year award budget totals $1,650,000. This research is Phase II of the overall project, with the initial Phase I project running from 2022 to 2023. The Biden administration has set a goal of net-zero greenhouse gas (GHG) emissions by 2050, and the DOE supports projects that help the US reach that goal.

What to do with a problem like waste coal?

Coal has been used as a source of energy since the 1880s, and one of the byproducts of using it is coal waste, which can contain arsenic, chromium, mercury, and other harmful substances. In 2019, coal use produced 2,907 million tons of coal waste, which can be stockpiled for years. As it sits, waiting for some type of proper disposal, coal waste presents several hazards to nearby communities and workers. These hazards could include spontaneous fires, which can release toxins and greenhouse gasses (methane and CO2), and toxic metals, which may leach into groundwater and flow into streams. This stored coal is also a wasted resource, with about 60% of the waste still containing viable calorific value.

To eliminate such hazards to human and natural life, and to reclaim and use the waste, researchers are investigating ways to put waste coal and other carbon-based biomass materials (such as wood waste and agricultural residues) and waste plastics to use, specifically as hydrogen. This process is known as gasification, which involves, very basically, introducing a carbon-based material to oxygen and high heat (above 700 degrees Fahrenheit) in a reactor vessel called a gasifier. Gasification can use these waste feedstocks to create syngas, a substance that can be processed into hydrogen. The process emits fewer pollutants than coal combustion. Gasification-produced hydrogen can also help the US increase its use of hydrogen, a fuel that emits fewer GHG, in line with Biden Administration goals.

Phase I: Create the process

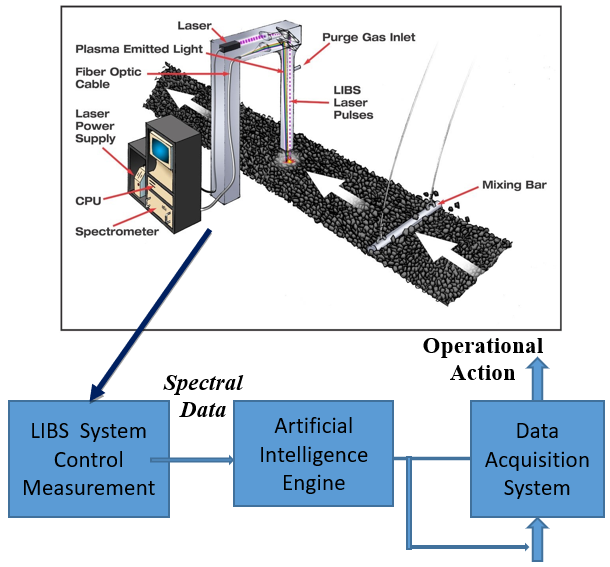

ERCo and the ERC have been working for more than a decade on joint projects which Romero characterizes as “crosscutting technologies, enhanced by artificial intelligence, including smart software for applications in the energy and power-generation industries.” This research suits the partnership, and in Phase I, Lehigh and ERCo focused on the development of the basic components of a system that can, on site and in real time, characterize the composition of feedstock blends before they enter the gasifier.

This initial phase used laser induced breakdown spectroscopy (LIBS) and machine learning (ML) to identify parameters in coal waste and/or biomass of interest to gasifier operators, such as carbon and volatile content, heating value and ash fusion temperatures. Waste coal and biomass can serve as hydrogen-fuel alternatives to legacy fuel sources such as coal. However, due to the variability inherent in these base materials, or feedstocks, they can present gasifier operators with operational challenges that can impact gasifier syngas quality and yield, as well as oxygen consumption.

LIBS works on a principle where a laser beam is shot at the flowing feedstock. The laser produces very hot, short-lived plasma, which emits radiation at element-specific wavelengths. The corresponding intensity at particular wavelengths can directly correlate with the concentration of particular elements in the sample. Machine-learning algorithms help improve LIBS measurement accuracy and precision. Overall, this would allow the system operator to optimize the use of oxygen in oxygen-blown gasifiers and decrease equipment downtime.

The novelty of this process, as Yao says, is that it’s a method that “fuses a powerful spectroscopic technique with advanced artificial intelligence algorithms into one integrated solution for monitoring properties of feedstock going into gasifiers, in real time and in situ.”

Phase I indicated that the results were very accurate across a range of samples from non-homogeneous feedstocks. This set the stage for Phase II, which is funded through the current grant.

Phase II: Optimize for real-life conditions

Phase II’s goal is to make the “Machine Learning Enhanced Laser Induced Breakdown Spectroscopy” (ML Enhanced LIBS) process commercially viable. This involves the use of ERCo’s commercial gasifier, measuring material blends composition as it moves along a conveyor belt, incorporating a greater variety of materials into the training of the machine-learning algorithms.

While Romero, Yao, and their colleagues at ERCo applied this technology to coal waste and biomass processing, the researchers also see applications in other fields. While Romero notes possibilities for its use in the mining and cement industry, Yao adds that any industry that “requires feedstock characterization, including additive manufacturing, biomass utilization, mining and cement industries” could benefit from its use.